In the bustling world of industry, where the hum of machinery and the whirl of activity never cease, there lies an unsung hero that ensures the safety and comfort of those who toil within these walls: industrial ventilation. This essential system works tirelessly to purify the air, removing harmful contaminants like dust, fumes, and gases, thus creating a healthier environment for workers. Whether it’s through dilution ventilation, which mixes clean air with contaminated air, or local exhaust ventilation, which captures pollutants at their source, the goal remains the same: to safeguard the well-being of employees.

As we delve into the intricacies of industrial ventilation, we’ll explore its importance, the various systems in place, and the regulations governing it, all while highlighting its pivotal role in enhancing workplace safety and productivity. Welcome to the world of industrial ventilation, where clean air contributes to a clearer future for workers everywhere.

What is Industrial Ventilation?

Industrial ventilation is a pivotal system aimed at promoting the safety and comfort of workers in various industrial environments, including manufacturing and processing facilities. Its foremost objective is to manage the indoor air quality by efficiently removing or diluting harmful airborne contaminants such as dust, fumes, vapors, and gases. There are two principal types of industrial ventilation:

- Dilution ventilation, which aims to reduce the concentration of air contaminants by mixing contaminated air with clean air.

- Local exhaust ventilation, which targets contaminants at their source, preventing them from dispersing into the workplace environment.

The inquiry into industrial ventilation often stems from a diverse interest base, encompassing concerns over health and safety regulations, technical details of ventilation systems, and strategies for enhancing workplace productivity through improved air quality. This indicates a broad search intent, from understanding how these systems can protect worker health to ensuring compliance with legal standards and fostering more comfortable and efficient working conditions. Embedded within the discourse on industrial ventilation is its critical role in preventing occupational diseases, adhering to environmental and safety regulations, and enhancing operational efficiency.

Effective ventilation systems not only underscore a company’s dedication to maintaining a high standard of workplace safety but also reflect its commitment to environmental responsibility and the well-being of its employees.

Why is Industrial Ventilation Important?

Industrial ventilation is crucial for creating a safe and comfortable work environment. It plays a key role in removing contaminated air, which is essential for protecting workers from harmful substances like dust, fumes, and gases. This process is vital for controlling air quality within industrial spaces, where airborne contaminants can pose serious health risks.

By regulating temperature and preventing equipment from overheating, industrial ventilation systems contribute to a more efficient and productive workplace. They help in reducing the risk of respiratory diseases by ensuring that hazardous substances are effectively removed from the air, thereby improving overall workplace comfort. The importance of industrial ventilation extends to compliance with safety and health regulations.

It is instrumental in helping businesses meet Occupational Safety and Health Administration (OSHA) standards and adhere to American Conference of Governmental Industrial Hygienists (ACGIH) guidelines. This not only safeguards the health and well-being of employees but also demonstrates a company’s commitment to maintaining high standards of workplace safety and environmental responsibility. Understanding the critical role of industrial ventilation aligns with the search intent of those looking for effective HVAC solutions to manage air quality in both residential and commercial settings.

It underscores the system’s importance in health protection, legal compliance, and operational efficiency.

Removes Contaminated Air

Industrial ventilation systems are pivotal in extracting harmful substances like dust, fumes, and gases. This critical function ensures a safer work environment by significantly reducing workers’ exposure to potential health hazards.

Controls Air Quality

These systems play a vital role in maintaining the quality of air within industrial spaces by diluting and removing airborne contaminants. Keeping the air clean is essential for complying with health and safety regulations and fostering a healthier work environment.

Regulates Temperature

Effective ventilation is key to regulating the temperature in industrial facilities. By preventing excessive heat, it creates a more comfortable environment for employees, which can lead to enhanced productivity.

Protects Equipment from Overheating

By preventing overheating, industrial ventilation contributes to the longevity of machinery and equipment. This not only reduces the risk of equipment failure but also ensures operational efficiency and productivity.

What are the Types of Industrial Ventilation Systems?

Industrial ventilation systems fall into two primary categories, each tailored to effectively manage air quality and ensure worker safety within industrial environments.

- Local Exhaust Ventilation: This type is engineered to capture contaminants at their source, preventing them from dispersing into the workplace air. Ideal for removing hazardous substances directly from where they are emitted, local exhaust ventilation is crucial for tasks that produce dust, fumes, gases, or vapors.

- General (Dilution) Ventilation: In contrast, general ventilation works by diluting contaminated air with clean air, thereby reducing the concentration of airborne contaminants throughout the entire space. This system is beneficial for maintaining overall air quality in larger areas where source capture is impractical.

Together, these systems underscore the comprehensive approach needed to safeguard air quality in industrial settings, ensuring a safer and healthier work environment for all employees.

Local Exhaust Ventilation

Local exhaust ventilation is specifically designed to capture contaminants right at their source, effectively preventing harmful substances such as dust, fumes, and gases from contaminating the workplace air.

Captures Contaminants at the Source

This system focuses on the immediate containment of hazardous materials at the point of emission, ensuring that pollutants are controlled before they have a chance to spread into the broader environment.

General (Dilution) Ventilation

General (dilution) ventilation systems aim to reduce the concentration of airborne contaminants by blending contaminated air with clean, fresh air, thereby diluting the pollutants present in the environment.

Reduces the Concentration of Airborne Contaminants

Suitable for larger spaces where source capture is impractical, this approach significantly lowers the overall levels of pollutants, contributing to the maintenance of healthier air quality throughout the entire workplace.

How Does Local Exhaust Ventilation Work?

Local exhaust ventilation functions by immediately capturing contaminants at their source, preventing them from spreading into the workplace air. This system utilizes hoods designed to enclose or be positioned close to the point where contaminants are generated, effectively trapping harmful substances. The contaminated air is then transported through ducts to a filtration or purification system, where dangerous particles are removed.

Finally, clean air is recirculated back into the environment. By concentrating on the precise area of emission, local exhaust ventilation offers a focused solution for preserving air quality and safeguarding worker health in various industrial scenarios.

Uses Hoods to Capture Contaminants

Local exhaust ventilation systems utilize hoods to effectively capture contaminants right at their source. Positioned near or directly over the emission point, these hoods play a crucial role in trapping harmful substances, preventing them from entering the workplace air.

Ducts Transport Air to Filtration Systems

Following capture, ducts serve as the conduits through which the contaminated air is transported to filtration systems. These systems are adept at purifying the air by removing pollutants, ensuring the circulation of clean air back into the workplace environment.

Also Read: Explore the Warmth: Your Complete Guide to Choosing the Right Heating System

What are the Components of a General Ventilation System?

A general ventilation system consists of several essential components designed to work in harmony to maintain indoor air quality and comfort.

Together, these components form the structural framework of a general ventilation system, each playing a vital role in promoting a healthy, comfortable, and safe indoor environment.

Air Intake

Air intake is the gateway that brings fresh air into the system, crucial for replenishing the indoor environment with clean, outdoor air. This is the starting point of the ventilation process, where fresh air is drawn from the outside into the system. It’s crucial for introducing clean air to dilute and replace contaminated indoor air.

Filters

Filters are key components that remove particles from the air, including dust, pollen, and other contaminants, ensuring the air is purified before it circulates. Acting as a barrier to airborne contaminants, filters clean the incoming air by trapping particles such as dust, pollen, and other pollutants, ensuring that the air circulated within the space is purified.

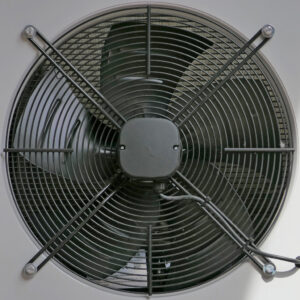

Fans

Fans are instrumental in circulating air through the system, maintaining a steady flow of air to ensure uniform air quality and temperature throughout the space. These are the driving force behind the air movement, fans propel the air through the system and ensure its distribution throughout the facility. They play a key role in maintaining consistent air flow and quality.

Ducts

Ducts serve as the channels through which air travels, efficiently distributing the filtered and conditioned air to various parts of the building. Serving as the airways of the system, ducts transport the filtered air from the fans to various parts of the building. They are critical for the even distribution of clean air, ensuring that all areas receive adequate ventilation.

Also Read: How To Clean HVAC Ducts And Improve Air Quality

What Factors Should Be Considered When Designing an Industrial Ventilation System?

When embarking on the design of an industrial ventilation system, several critical factors must be taken into account to ensure its effectiveness and efficiency.

These factors collectively shape the approach to developing a ventilation system that not only safeguards worker health and safety but also promotes operational efficiency and sustainability.

Type of Contaminants

The type of contaminants, including particulate matter, gases, and vapors, is a critical factor. It dictates the design and functionality required of the ventilation system to ensure effective removal. Understanding the specific contaminants present in the environment, whether they be particulate matter, gases, or vapors, is essential. This knowledge dictates the system’s design to ensure it can capture and remove these hazards effectively.

Volume of Air Needed

Determining the volume of air needed hinges on the size of the space and the levels of contaminants. This precise calculation is vital for creating a safe and comfortable environment. The size of the space and the level of contaminants influence the amount of air that needs to be circulated. Accurate calculations are necessary to determine the volume of air needed to maintain a safe and comfortable workspace.

Energy Efficiency

Achieving energy efficiency means minimizing power consumption while still ensuring the system’s effectiveness. This is key to reducing operational costs and supporting environmental sustainability. Designing a system that is energy-efficient is paramount. The goal is to minimize power consumption while still achieving optimal performance, thereby reducing operational costs and lessening the environmental impact.

What are the Maintenance Requirements for Industrial Ventilation Systems?

Maintaining industrial ventilation systems is crucial for ensuring their efficiency and longevity. Together, these maintenance tasks are fundamental in keeping the ventilation system operational, safeguarding worker health, and upholding safety standards. Key maintenance activities include:

Regular Cleaning

Regular cleaning is essential to prevent the buildup of dust and debris, ensuring that airflow is maintained and the system operates at peak efficiency. It’s essential to prevent the buildup of contaminants that can hinder airflow and degrade air quality. This helps in maintaining optimal performance of the system.

Filter Replacement

Filter replacement is critical for the system’s continued ability to effectively remove contaminants from the air, thus safeguarding the indoor air quality. To continue effectively removing contaminants from the air, filters must be regularly replaced. This is critical for preserving the air quality and the system’s efficiency. Routine inspections are necessary to detect wear and potential failures early. Prompt identification allows for timely repairs or adjustments, preventing larger issues and ensuring the system’s reliability.

System Inspection

Routine system inspection is key to the early detection of wear and potential failures, allowing for timely maintenance and repairs to keep the system operational.

How Does Industrial Ventilation Impact Worker Health?

Industrial ventilation is crucial in protecting worker health by reducing exposure to harmful contaminants. By removing or diluting airborne pollutants such as dust, fumes, gases, and vapors, these systems play a key role in lowering the risk of respiratory diseases and other ailments linked to poor air quality. Furthermore, ensuring a comfortable work environment through effective ventilation improves overall workplace comfort, which can lead to enhanced well-being, reduced stress, and increased productivity among workers.

Therefore, industrial ventilation is not merely a compliance measure but a fundamental component in fostering a healthier and more productive work environment.

Reduces Exposure to Harmful Contaminants

Industrial ventilation plays a critical role in significantly reducing workers’ exposure to harmful contaminants, effectively ensuring a cleaner, safer breathing environment by removing or diluting airborne pollutants.

Lowers Risk of Respiratory Diseases

By effectively minimizing workers’ contact with hazardous substances, industrial ventilation substantially lowers the risk of developing respiratory diseases, safeguarding workers’ health and promoting a healthier work life.

Improves Overall Workplace Comfort

Efficient ventilation systems contribute to enhanced workplace comfort by regulating temperature and maintaining optimal air quality. This leads to improved productivity and greater worker satisfaction, creating a more conducive and pleasant work environment.

What Regulations Govern Industrial Ventilation?

Industrial ventilation is subject to a comprehensive set of regulations aimed at ensuring workplace safety and environmental well-being. The Occupational Safety and Health Administration (OSHA) standards set forth the minimum requirements for ventilation, focusing on the imperative to control exposures to airborne contaminants effectively. Alongside, the American Conference of Governmental Industrial Hygienists (ACGIH) guidelines provide detailed best practices for the design of ventilation systems, with the goal of optimizing air quality and safeguarding worker health.

These pivotal regulations and guidelines serve as the cornerstone for businesses in implementing efficient and compliant ventilation systems, ensuring adherence to legal and safety standards while fostering a healthful work environment.

Occupational Safety and Health Administration (OSHA) Standards

OSHA standards are pivotal in setting the minimum ventilation requirements to safeguard workplaces by mitigating exposure to airborne pollutants.

American Conference of Governmental Industrial Hygienists (ACGIH) Guidelines

ACGIH guidelines are instrumental in providing best practices for ventilation design, focusing on enhancing air quality and ensuring the health and safety of workers in industrial environments.

Ensuring Safety Work Environment Through Effective Air Management

Industrial ventilation stands as a fundamental aspect of creating a safe and healthy work environment. Through the strategic removal or dilution of airborne contaminants, these systems are essential in protecting worker health, ensuring compliance with safety regulations, and enhancing operational efficiency. The careful design and maintenance of industrial ventilation systems, guided by OSHA standards and ACGIH guidelines, necessitate a thorough consideration of various factors such as contaminant types, air volume requirements, and energy efficiency.

As the industrial landscape continues to advance, the imperative for adapting and optimizing ventilation systems grows ever more critical, underscoring their role not just in meeting regulatory standards but in promoting a productive, safe, and healthy workplace for all.

Ready to optimize your industrial ventilation system? Contact Callidus Air today for expert solutions tailored to your specific needs. Our team of professionals can help you design, install, and maintain a state-of-the-art ventilation system that ensures worker safety, regulatory compliance, and operational efficiency.